Click for application examples…

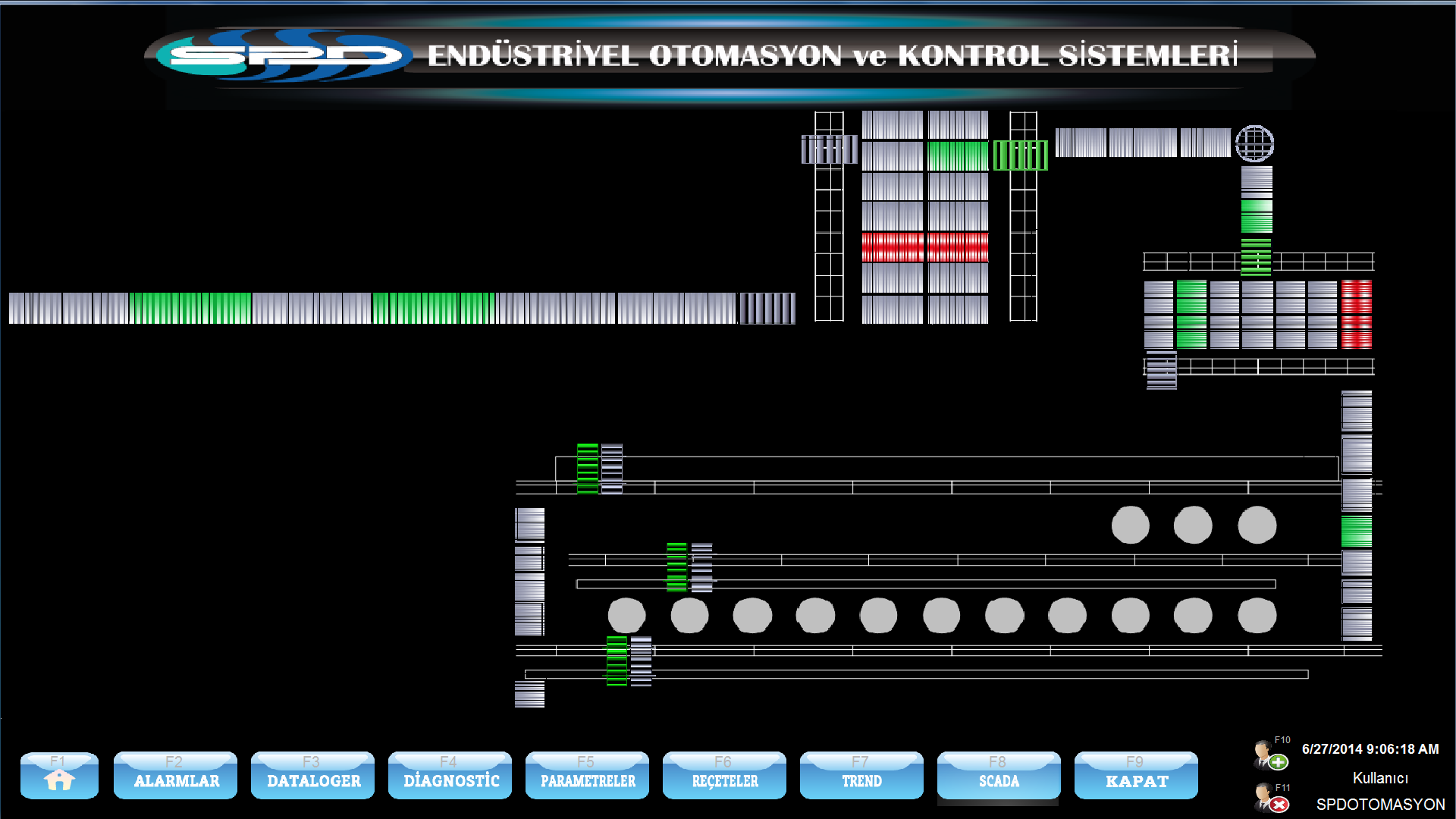

Scada means ”Supervisory Control And Data Acquisition”. In short it is a system, controlled by computers, communication tools, sensors and other kind of devices. Mainly it splits into two; Energy Scada (electric, water, gas) and Process Scada (fabric-facility automation).

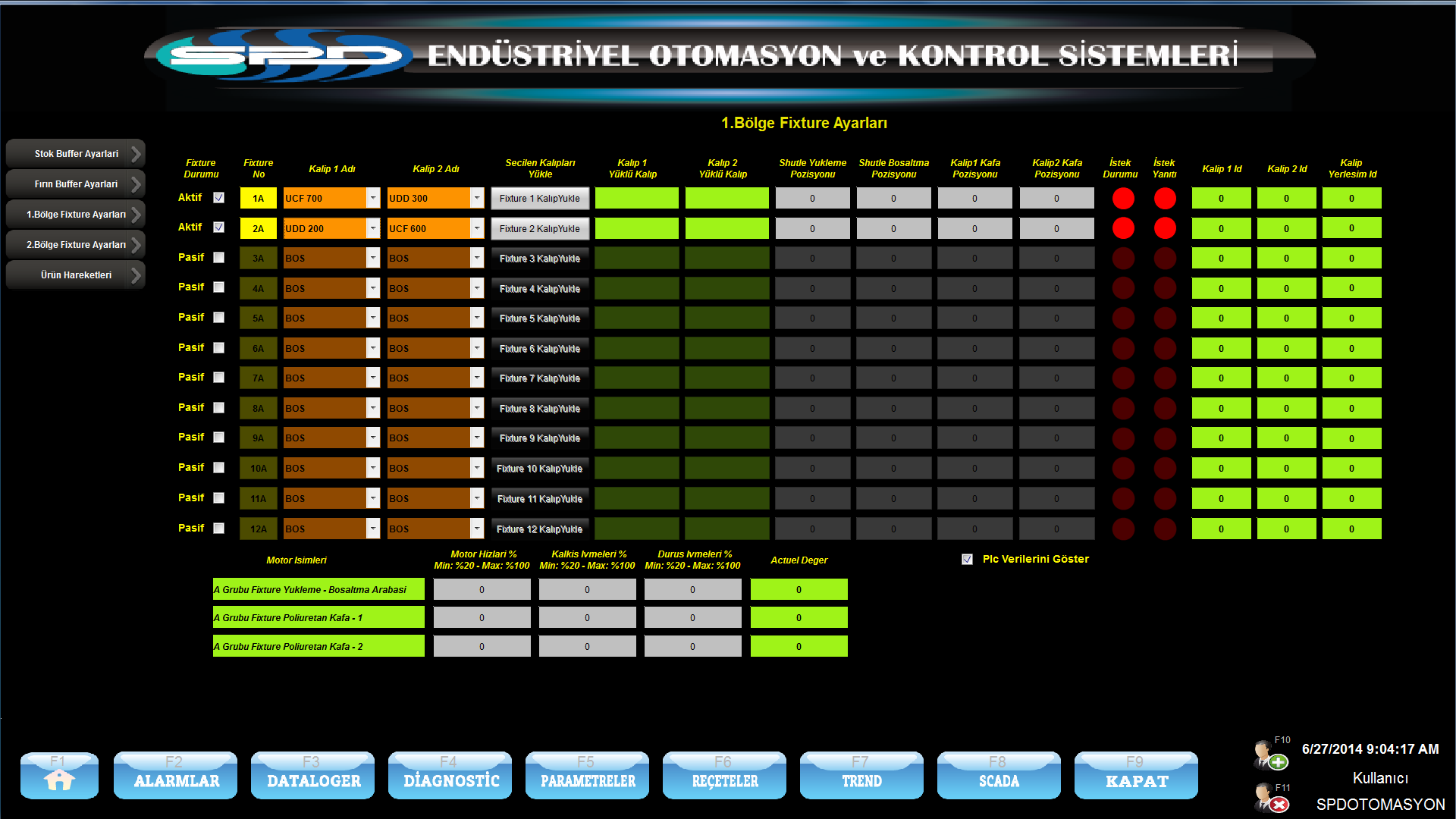

Scada systems are carving out a substructure together with some tools like RTU,PLC e.t.c. that are used at processes like raw material, production and follow up of finished goods, for production control and followings of the fabrics.

With the possibility that this substructure allows, production resources planning and business resources planning systems can lead to a ideal structure. The aim is to create the structure with min. costs and max. quality and productivity.

To benefit from the highest efficiency of facilities can only be achieved by the managers having full knowledge of the operation and production informations.

Scada SW packages are taking over substructure software missions and ensure that all layers of the company work in accordance by connecting to networks in and out of the fabrics. Scada provides everyone in the facility, real-time and detailed information.

Mostly used areas;

Scada systems, hydroelectrics, nuclear power generation, gas production and processing facilities, gas, oil, running pumps valves and flow measuring equipment for chemical substance and waterpipelines, control of the on/off switches on power transmission lines that are of kilometres long and balancing of instantaneous load changes in the lines.